Optimizing BESS Performance with HVAC and Ventilation Simulation Technology

When batteries are charged or discharged, a chemical reaction takes place inside the battery, which produces heat. This is known as the “Joule heating” effect. The amount of heat produced depends on several factors, such as the battery chemistry, the charging or discharging rate, and the temperature of the battery.

The temperature of the environment in which the BESS is located can significantly affect its performance and lifespan. If the BESS is located in an environment that is too hot or too cold, it can lead to accelerated degradation of the battery cells, reduced capacity, and decreased efficiency. In some cases, the heat produced by the battery can be significant and can lead to temperature increases that can affect the performance and lifespan of the battery. TROES’ HVAC system is responsible for removing this heat to ensure safe operation.

A HVAC system can help to regulate the temperature of the environment around the BESS, ensuring that it operates within the optimal temperature range. For example, if the BESS is located in a hot environment, the HVAC system can provide cooling to prevent the temperature from rising too high. Similarly, if the BESS is located in a cold environment, the HVAC system can provide heating to maintain the optimal temperature range.

A well-designed HVAC system can also help to manage humidity levels, which can be another factor that affects the performance and lifespan of the BESS. High humidity levels can cause corrosion and other forms of damage to the BESS, while low humidity levels can lead to static electricity and other issues.

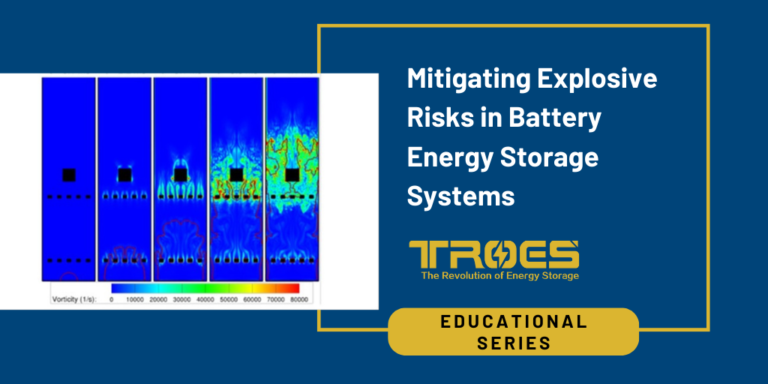

Ventilation simulation technology accurately assesses the thermal performance of battery energy storage systems (BESS). Advanced ventilation simulation technology for battery storage is a computer-based tool that can be used to simulate and optimize the ventilation system for battery storage facilities. The technology uses computational fluid dynamics (CFD) to model the airflow and temperature distribution within the battery storage facility and the ventilation system.

The CFD simulation model takes into account various factors such as the size and layout of the battery storage facility, the number and location of the batteries, the ventilation system design, and the outdoor climate conditions. The simulation model can then predict the airflow and temperature distribution within the facility and identify potential hotspots where heat could accumulate.

Based on the simulation results, the ventilation system design can be optimized to ensure adequate ventilation and cooling of the battery storage facility. This can help prevent overheating of the batteries, which can lead to performance degradation and safety risks.

TROES offers this advanced technology to our customers for better quality service, as a properly designed HVAC system can help to maintain the optimal temperature and humidity conditions for the BESS, leading to improved performance, increased efficiency, and longer lifespan of the batteries.